HMIs: What Are They and How to Use Them

Production and manufacturing have become increasingly complex, and developments in technology are further refined and implemented on an ever-increasing scale. Almost every facet of life has been touched by technological innovation in some way.

This blog will cover one specific innovation, HMIs, or Human Machine Interfaces. Keep reading to learn what an HMI is, where and how HMIs are typically used, who uses them, and where the technology is headed.

What is an HMI?

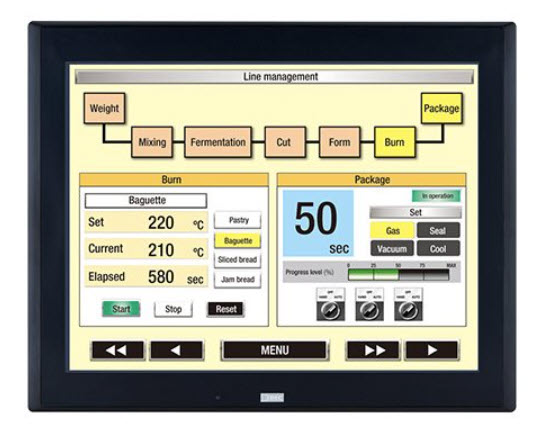

A Human-Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, system, or device. Common HMI devices include touchscreens and keyboards. The term “HMI” can technically be applied to any screen that allows a user to interact with a device, but HMI is most commonly used within the context of an industrial process.

An HMI can be very complex, but on the surface, it works much like our everyday items. For example, think about how you interact with the HVAC system in your home. If you have a smart system, you likely have a thermostat with a screen that helps you to regulate the temperature.

HMIs are beneficial because they digitize and centralize information. They translate data from industrial control systems into readable visual representations, including charts, graphs, and other useful data that help keep certain systems properly monitored and safely optimized.

Who uses HMI?

HMIs are used in several different sectors. Industrial uses are among the most practical use applications for HMIs because they allow interaction with equipment and systems to optimize production and business processes. Factory operators often use HMIs to control and automate machinery and their production lines.

Industries using HMI include:

• Energy

• Food and beverage

• Manufacturing

• Oil and gas

• Power

• Recycling

• Transportation

• Water and wastewater

The most common roles that interact with HMIs are operators, system integrators, and engineers, particularly control system engineers. HMIs are essential resources for these professionals, who use them to review and monitor processes, diagnose problems, and visualize data.

Common Uses of HMIs

HMIs can be a variety of different elements, including screen displays mounted on machines in the factory, advanced touchscreens, multi-touch-enabled control panels, push buttons, computers with keyboards, mobile devices, or a tablet.

In industrial settings, HMIs can be used to visually display data, track production time, trends, and tags, oversee KPIs, monitor machine inputs and outputs, and much more. HMIs are usually deployed on Windows-based machines and communicate with programmable logic controllers (PLCs), as well as input/output sensors to display information.

HMI screens can be used for a single function, like monitoring and tracking, or for performing more sophisticated functions, like switching machines off or increasing production speed, depending on how they are implemented.

Before HMIs were developed, technicians and operators had to manually check equipment systems and mechanical processes, recording data by hand. This can leave a lot of room for error and even missed problems, which are both costly but avoidable issues. By allowing PLCs to communicate real-time information straight to an HMI display, HMI technology eliminates the need for manual processes and reduces many costly problems caused by a lack of information or human error.

The Future of HMIs

In the past decade, changing operational and business needs have prompted innovations in technology, specifically HMI. It’s becoming more common to see evolved and advanced forms of HMI technology, including high-performance HMIs, touch screens, mobile devices, remote monitoring, edge-of-network HMIs, and more.

Continued modernization of these interfaces creates more opportunities for interaction and analysis, which leads engineers to continue to push the boundaries of the technology and what it can do.

As data takes on an increasingly essential role in manufacturing, the future looks bright for HMI. This technology has come a long way and its potential for growth remains virtually limitless.