ALL THE BENEFITS OF ACI’S NEW INSTRUMENT GAS SUPPLY COLUMN

In the United States alone, there are over 2 million miles of fuel pipelines carrying oils and natural gas. To move natural gas through the pipeline, there are typically a series of compressors that are used to create pressure differentials, pushing gas flow from areas of high pressure to lower pressure.

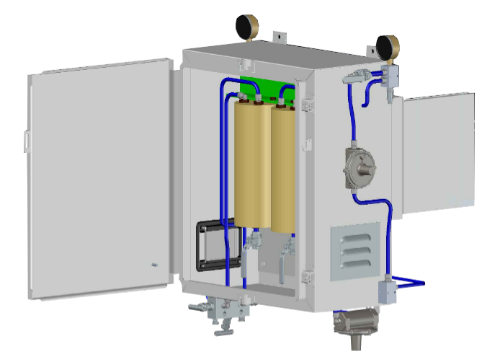

To ensure equipment is running within usable pressure limits, ACI Controls manufacturers custom instrument gas supply columns for natural gas pipelines. This stand-alone unit can replace the need for a compressor in pipeline applications. ACI Controls supplies local gas utility companies with the ACI-IC, allowing gas utility companies in the New York and Pennsylvania area to be confident in managing natural gas distribution pressure. Here are some of the important benefits you can expect from the ACI-IC.

Precise and reliable operation.

Following a thoroughly structured process, the ACI-IC ensures a smooth, refined solution for pipeline applications. Unfiltered, water-dense natural gas enters the ACI-IC Series inlet. Gas is filtered and pressure is reduced for instrument consumption. The gas supply then exits the filter and begins the heating process with a catalytic coil heat source. When the gas exits the heater assembly, it is tubed to a manifold for customer tap. Clean, dry heated gas exits the unit and the process is complete.

The ACI-IC makes use of a radiated heat source to minimize the Joules-Thompson cooling effect that is associated with high-pressure reduction of natural gas. This temperature reduction can lead to freezing problems and hydrate formation within the regulators.

Maximizes efficiency.

Downtime in any application can cause a lot of losses, including time and money. With the rugged, compact design of the ACI-IC, you can expect easy installation and service. Filtration can be replaced without halting operation, and the ACI-IC is field serviceable with readily available parts. This minimizes downtime, boosting productivity and efficiency.

Completely customizable.

The ACI-IC can be completely customizable to meet specific application requirements. Some of the customizable options include:

- Optional thermostat to adjust catalytic heater temperature

- Filter options to 72000 SCFH flow capacity

- Optional fiberglass insulated enclosure for outdoor installation

- Adjustable pressure outputs

Want more information?

You can download our ACI-IC brochure here. ACI’s design engineers can work with you from piping and instrumentation diagram to startup.