THE IMPACT OF ROBOTIC TECHNOLOGY IN THE MANUFACTURING INDUSTRY

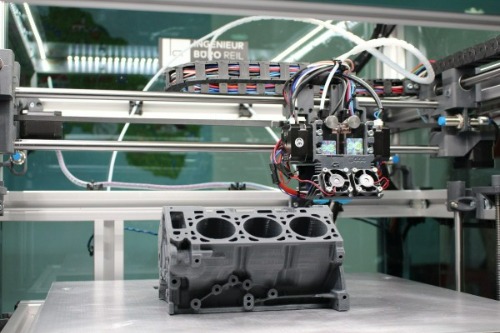

Technology is continuously progressing in the manufacturing industry. With new developments in automation, the industry is introducing the use of robots in the workplace. Since the technology is so new, there are many concerns that robots will essentially take over manufacturing, leaving people without jobs and changing the industry as a whole.

Technology is continuously progressing in the manufacturing industry. With new developments in automation, the industry is introducing the use of robots in the workplace. Since the technology is so new, there are many concerns that robots will essentially take over manufacturing, leaving people without jobs and changing the industry as a whole.Though the concerns are valid and change can be frightening, the introduction of robots in the industry actually has a positive impact on both manufacturing and the employees.

There are many ways in which industrial robots affect the workplace, including the creation of new, more intellectually concentrated jobs, the promotion of productivity, cost and time efficiency, and even the promotion of a greener workspace. Here is a closer look at how robots are impacting manufacturing:

Robots allow the creation of new jobs in different industries.

A common concern of manufacturing employees is that robots are going to take away their jobs. However, this is not the case. Robots have the ability to eliminate undesirable jobs that are either mundane or too dangerous and replace them with jobs that are more appealing, like engineering or programming.

Through the elimination of unappealing jobs, labor is freed up, allowing people to become more skilled at a specific craft. Instead of thinking of this as a loss of jobs, it should be looked at as an opportunity for the creation of new jobs in different fields.

While there may be less people on the actual factory floor, more will be getting done. Manufacturing employees will become more skilled in different disciplines, will be better paid for their work, and will be creating more valuable products, like technology that will help them become even more time and cost effective.

Robots promote efficiency in manufacturing.

Productivity and performance are major components to any successful workplace. Time is valuable, and one major impact of the addition to robots regarding time is the idea that robots can be programmed to fit any schedule. They have the ability to run on hours that do not typically fit into a human employees schedule, and can essentially work 24/7. This maximizes the use of time and productivity.

Since robots can move quickly and efficiently, there would be a great reduction of mistakes that could potentially be made by a human hand. Multitasking, which may be hard for human employees to complete without making mistakes, can easily be done by robots, which will eliminate the need for extra, less efficient machinery. This allows for a steady flow of production that will promote productivity and efficiency.

Not only are robots cost effective in the workplace, they also can have an impact on local economies. Through a boost in productivity, companies will no longer have to look to other countries as a source of labor. With the implementation of robots, all labor can be done locally, and in a manufacturers own space.

Robots in the workplace promotes a greener environment.

There is a growing interest in green manufacturing all around the world. To be “green” means energy efficiency and environmentally friendly manufacturing processes.

By replacing manufacturing floor workers with robots, the environment inside of the factory can change. Since there are no longer humans working, there do not have to be any regulations on the temperature inside of the factory, or whether the lights are on or off. By reducing energy involving air conditioning, heat and lighting the facility, a greener workplace will be promoted.

The efficiency and precision of robots will decrease the amounts of scraps that are created within the workplace. Less scraps is less waste that enters the environment. Impacting the environment through waste reduction and energy conservation will allow for a company to become green and help conserve the environment.

The introduction of robots into the manufacturing industry has the ability to majorly impact both the industry itself, and the rest of the world. Though making the switch from human employees to robots may seem like a big leap and some may be concerned about the survival of manufacturing, the lasting impact will positively affect the jobs within the industry, the overall productivity and efficiency, and the sustainability of the environment.

Want to talk more about the impact of robots in manufacturing?

We’d love to help you out. Give us a call at 1.800.333.7519 or contact us to speak with an ACI representative today.

Tags

oil and gas

filtration

food industry

compressed air

condition monitoring

power generation

corrosion

nitrogen generators

safety

connectors

mettler toledo

process control

Cleaner

Smarter and More Efficient Filtration Solutions

Combustion Air Blowers

Differential Pressure

Temperature Transmitters

hmi

human machine interface

ppe

covid19

covid 19

prevent corrosion

indoor air quality

single ferrule

tube fittings

parker single ferrule compression fittings

parker single ferrule fittings

supercase ferrule hardening

ferrules

supercase

compressed air filtration

compressed air contamination

parker compressed air filtration

heat treat

industrial heat treating

food and beverage

power industry

sustainability

combustion

combustion types

cement industry

dust collection

furnaces

industrial furnaces

plant efficiency

energy management

corrosion prevention

moisture control

electrical cabinets

valves

valve automation

water treatment

thermal oxidizer

temperature control

nitrogen generator

energy efficiency

digitization trends

instrument gas

supply column

oil and gas industry

all of the hidden costs of gas cylinders

calibration

equipment lifespan

extending equipment lifespan

sterile filtration

trends

compressed gas

heat tracing

water chilling

compressed air filters

manifolds

robotics

robotic technology

robotics in manufacturing

cost effective manufacturing

lead

reduce lead

animal watering systems

employee health

improving employee health

manufacturing

productivity improvement

drinking water

thm

thm analyzer

parker thm water analyzer

parker online thm analyzer

apps

manufacturing apps

process improvement

tubing

plant safety

safety tips

leak free connections

thermal mass flow

magnetrol

inline ball valves

nsf

ansi 61

nsfansi 61

back pressure

back pressure safety valves

safety valves

streamline process

condition monitoring process

mixing materials

compression fittings

dissolved oxygen

do measurement

optical do sensors

parker

parker hannifin

transmitters

industrial transmitters

smartline

smartline transmitters

downstream oil and gas

oil and gas filtration

industrial instrumentation

process control instrumentation

ph measurement

ph measurement best practices

ignition risk

risk avoidance

Show All

Posts

2024

March

2023

Elevating Customer Experience in Industrial Process Control Distribution: Top Expectations for Distributors

[03/04/24 01:59 PM]

The Advantages of Partnering with ACI Controls as your Industrial Products Stocking Distributor

[03/04/24 01:37 PM]

The Value of Continued Process Application and Skill Set Training for Manufacturing Maintenance Departments

[03/04/24 01:26 PM]

Navigating the Complexities of Burner Control Management in Furnace Processes

[03/04/24 12:50 PM]

10 Advantages of Using Variable Frequency Drives (VFDs)

[03/04/24 12:35 PM]

Navigating Process Filtration Products in the Food and Beverage Industry: Requirements and Challenges

[03/04/24 12:26 PM]

The Top 10 Benefits of On-Site Nitrogen Generators for Manufacturing Processes

[03/04/24 12:10 PM]

Pipe Heat Tracing

[03/04/24 10:38 AM]

Improving Manufacturing Efficiency: A Guide to Process Control

[03/01/24 10:48 AM]

January

December

2022

2021

Protecting Your Investment: The Critical Role of Balston Air and Gas Filters in Industrial Equipment

[12/07/23 09:52 AM]

Cleaner, Smarter and More Efficient Filtration Solutions

[12/03/23 10:42 PM]

Combustion Air Blowers

[12/01/23 10:23 PM]

November

August

Prioritization and Criticality in Manufacturing: What it Means to You

[08/28/23 11:37 AM]

Chart Recorders: What Are They and How Can They Help You Collect Accurate Data

[08/15/23 11:19 AM]

June

Everything You Need to Know About Fuel Water Separators (and Why Maintenance is Critical)

[06/20/23 03:12 PM]

The Differential Pressure Guide: The Basics You Need to Know

[06/15/23 02:43 PM]

May

April

March

What You Need to Know About Industrial Burners

[03/21/23 12:17 PM]

Differential Pressure Switches: What You Need To Know

[03/01/23 09:10 PM]

Buyer's Guide: What to Know Before Buying Temperature Transmitters

[03/01/23 09:01 PM]

January

September

2020

HOW TO STAY SAFE IN INDUSTRIAL HEATING APPLICATIONS

[09/30/21 03:47 PM]

3 WAYS THAT PPE WILL KEEP YOU SAFE IN THE WORKPLACE

[09/28/21 03:35 PM]

HOW TO PREVENT CORROSION IN OIL AND GAS APPLICATIONS

[09/28/21 01:29 PM]

August

July

June

May

2019

WHAT YOU NEED TO KNOW ABOUT FILTRATION IN THE FOOD AND BEVERAGE INDUSTRY

[05/19/20 04:01 PM]

WHAT YOU NEED TO KNOW WHEN SELECTING THE RIGHT INSTRUMENTATION TUBING

[05/04/20 04:13 PM]

April

EVERYTHING YOU NEED TO KNOW ABOUT THE HEAT TREATING PROCESS

[04/17/20 04:37 PM]

THE IMPORTANCE OF CONDITION MONITORING IN THE FOOD INDUSTRY

[04/09/20 04:40 PM]

March

WHY SUSTAINABLE TECHNOLOGY IS SO IMPORTANT IN THE POWER INDUSTRY

[03/18/20 04:48 PM]

THE MOST CORROSION-RESISTANT METALS FOR YOUR EQUIPMENT

[03/02/20 04:53 PM]

HOW TO BOOST STEAM GENERATION EFFICIENCY WITH GUIDED WAVE RADAR

[03/02/20 04:52 PM]

February

January

December

2018

BACK TO THE BASICS: 5 IMPORTANT CLASSIFICATIONS OF COMBUSTION

[12/16/19 05:45 PM]

HOW TO AVOID TURBINE FAILURES IN LNG PROCESSING PLANTS

[12/02/19 05:49 PM]

November

October

HOW TO REDUCE DUST COLLECTOR MAINTENANCE IN THE CEMENT INDUSTRY

[10/28/19 06:00 PM]

3 REASONS WHY INDUSTRIAL FURNACES ARE THE RIGHT SOLUTION

[10/02/19 06:11 PM]

HOW TO INCREASE PLANT EFFICIENCY WITH ENERGY MANAGEMENT

[10/01/19 06:14 PM]

September

4 THINGS YOU NEED TO KNOW ABOUT MAXON VALVES IN COMBUSTION SYSTEMS

[09/16/19 12:10 PM]

THE TOP 5 WAYS TO OPTIMIZE WATER MONITORING

[09/03/19 12:16 PM]

August

HOW TO AVOID CORROSION IN METAL PARTS

[08/19/19 12:33 PM]

SAVE ENERGY AND PREVENT DISRUPTIONS WITH NITROGEN GENERATORS

[08/05/19 12:39 PM]

July

THIS IS HOW STERILE FILTRATION IS CHANGING THE INDUSTRY

[07/23/19 03:41 PM]

HOW TO KEEP YOUR ELECTRICAL CABINETS DRY IN THE FOOD INDUSTRY

[07/08/19 03:45 PM]

June

May

HOW TO CHOOSE A WATER TREATMENT SYSTEM SUPPLIER FOR POWER GENERATION

[05/30/19 03:53 PM]

CASE STUDY: HOW TO SOLVE TEMPERATURE CONTROL ISSUES IN A THERMAL OXIDIZER

[05/13/19 04:02 PM]

April

A NEW ENERGY EFFICIENT NITROGEN GENERATOR IS LAUNCHING

[04/29/19 04:10 PM]

3 DIGITIZATION TRENDS TO LOOK OUT FOR IN THE OIL AND GAS INDUSTRY

[04/09/19 04:11 PM]

THE IMPORTANT KEY TO SUCCESSFUL NEW IOT TECHNOLOGY

[04/01/19 04:16 PM]

March

February

WHY FILTRATION IS SO IMPORTANT IN THE OIL AND GAS INDUSTRY

[02/26/19 02:03 PM]

WHY CHECK VALVES ARE SO IMPORTANT FOR HYDRAULICS

[02/13/19 02:04 PM]

3 REASONS WHY SUSTAINABILITY IS IMPORTANT FOR MANUFACTURING

[02/04/19 02:08 PM]

January

December

2017

HOW TO BE SAFE WHEN WORKING WITH COMPRESSED NITROGEN GAS

[12/17/18 02:25 PM]

WHY CALIBRATION IS IMPORTANT FOR MANUFACTURERS

[12/05/18 02:28 PM]

November

IS STAINLESS STEEL WORTH THE RISK IN FILTRATION?

[11/20/18 02:38 PM]

THE BEST TIPS FOR EXTENDING YOUR EQUIPMENT’S LIFESPAN

[11/06/18 02:40 PM]

October

WHY STERILE FILTRATION IS BETTER FOR ULTIMATE SUSTAINABILITY

[10/15/18 02:43 PM]

3 TRENDS IN THE OIL AND GAS INDUSTRY TO WATCH OUT FOR

[10/03/18 02:46 PM]

September

MAKE THE BEST SAFETY PLAN FOR COMPRESSED GAS

[09/17/18 02:50 PM]

EVERYTHING YOU NEED TO KNOW ABOUT THE INTEGRATION OF CONTROL SYSTEMS

[09/06/18 02:56 PM]

August

EVERYTHING YOU NEED TO KNOW ABOUT HEAT TRACING

[08/14/18 03:00 PM]

THE IMPORTANCE OF WATER CHILLING IN MANUFACTURING

[08/02/18 03:00 PM]

July

ALL OF THE BENEFITS SURROUNDING COMPRESSED AIR FILTERS

[07/16/18 03:09 PM]

WHY MANIFOLDS ARE SAVING THE DAY FOR ENGINEERS

[07/05/18 03:13 PM]

June

THE IMPACT OF ROBOTIC TECHNOLOGY IN THE MANUFACTURING INDUSTRY

[06/22/18 03:18 PM]

HOW TO ENSURE SAFER BOTTLED WATER WITH MICROFILTRATION

[06/07/18 03:23 PM]

May

HOW TO BOOST COST-EFFECTIVENESS IN MANUFACTURING

[05/24/18 03:31 PM]

HOW TO REDUCE LEAD FOUND IN ANIMAL WATERING SYSTEMS

[05/11/18 03:34 PM]

April

4 WAYS TO IMPROVE YOUR MANUFACTURING EMPLOYEES’ HEALTH

[04/24/18 03:40 PM]

WHY CONDITION MONITORING IS IMPORTANT FOR YOUR BUSINESS

[04/10/18 03:43 PM]

HOW TO IMPROVE PRODUCTIVITY IN MANUFACTURING

[04/04/18 03:53 PM]

March

February

5 MANUFACTURING APPS GUARANTEED TO IMPROVE YOUR PROCESSES

[02/28/18 04:01 PM]

HOW TO CHOOSE THE RIGHT CONNECTOR AND TUBING FOR YOUR APPLICATION

[02/08/18 04:06 PM]

January

December

TEN STEPS TO LEAK-FREE CONNECTIONS IN OIL AND GAS APPLICATIONS

[12/15/17 09:56 PM]

EVERYTHING YOU WANT TO KNOW ABOUT THERMAL MASS FLOW

[12/14/17 09:53 PM]

November

HAVE YOU HEARD? ALL INLINE BALL VALVES ARE CERTIFIED TO NSF/ANSI 61

[11/16/17 10:02 PM]

WHAT YOU NEED TO KNOW ABOUT BACK PRESSURE SAFETY VALVES

[11/09/17 10:08 PM]

October

HOW TO STREAMLINE YOUR CONDITION MONITORING PROCESS

[10/27/17 10:11 PM]

HOW TO MIX MATERIALS IN CORROSIVE ENVIRONMENTS

[10/13/17 10:15 PM]

September

5 BIG REASONS TO SWITCH TO OPTICAL DO MEASUREMENT

[09/27/17 10:23 PM]

HOW TO USE NITROGEN GENERATORS FOR FOOD PRESERVATION

[09/14/17 10:27 PM]

August

3 IMPORTANT REASONS TO USE SMARTLINE TRANSMITTERS

[08/24/17 10:33 PM]

WHAT YOU NEED TO KNOW ABOUT DOWNSTREAM OIL AND GAS FILTRATION

[08/09/17 10:39 PM]

July

4 BIG BENEFITS OF PROCESS CONTROL INSTRUMENTATION

[07/25/17 10:47 PM]

THE COMPLETE GUIDE TO THE BEST PROCESS CONTROL PRACTICES

[07/06/17 10:47 PM]

June